Failed capacitors are the #1 cause: followed by contactors and compressors

If your outdoor AC unit is completely silent while the indoor blower is running, the most likely culprit is a failed capacitor. Capacitors are the single most common point of failure in residential air conditioning systems: they store electrical charge to provide the initial jolt needed to start the compressor motor. When they fail, the outdoor unit won't turn on at all.

The good news: a capacitor replacement typically costs $150-$300 including the service call. The bad news: you can't safely diagnose this yourself. Capacitors store dangerous voltage even when the unit is powered off, and opening the electrical panel on your outdoor unit should only be done by a licensed technician.

In this guide, we'll walk through the simple diagnostic steps you can safely perform yourself, explain what different symptoms mean, and help you understand when it's time to call for professional service.

Quick checks you can do yourself

Before calling for service, there are five simple diagnostic steps you can safely perform. These checks take about 15 minutes and can sometimes identify the problem without needing a technician.

What each symptom means

Different failure modes produce different symptoms. Understanding what you're hearing (or not hearing) can help you communicate the problem to a technician and estimate repair urgency.

| Component | Urgency | Details |

|---|---|---|

| Failed Capacitor | Medium: can wait 1-3 days | |

| Bad Contactor | Medium: can wait 1-3 days | |

| Faulty Control Board | Medium: can wait 1-3 days | |

| Compressor Failure | Low: but expensive | |

| Low Refrigerant (Leak) | Medium: can wait 2-4 days |

Safety warnings: never open the electrical panel

Many online guides suggest checking the capacitor yourself; this is dangerous advice. Even if you shut off the breaker and disconnect switch, the capacitor will still hold a charge. HVAC technicians use insulated tools and capacitor discharge devices to safely drain stored voltage before touching internal components.

Other safety rules when troubleshooting your AC unit:

- Don't bypass safety switches. If you see a pull-out fuse block or disconnect switch in the OFF position, there's a reason. Don't override it without understanding why it was shut off.

- Don't force a stuck fan. If the outdoor fan blade isn't spinning, don't try to manually spin it. A stuck motor may have seized bearings or a failed capacitor; forcing it can cause further damage.

- Don't spray water inside the unit. While it's safe to gently rinse the exterior coils from the outside, never spray water directly into the electrical compartment or control box.

- Don't attempt refrigerant work. Federal EPA regulations require certification to handle refrigerant. DIY refrigerant recharge is illegal, dangerous, and likely to make the problem worse.

What to expect from a professional diagnosis

When you call for service, a licensed HVAC technician will perform a systematic diagnostic process to identify the exact cause of the failure. Here's what a typical service call includes:

1. Visual inspection and safety check

The technician will inspect the outdoor unit for visible damage, debris, or signs of electrical failure. They will verify that all disconnect switches are functioning and that the unit is receiving proper voltage from the breaker panel.

2. Electrical testing with multimeter

Using a multimeter, the technician will test voltage at the contactor, capacitor, and compressor terminals. This identifies whether the failure is in the control circuit (24V low voltage), power supply (240V high voltage), or the component itself. Capacitors are tested for microfarad (µF) rating: most dual-run capacitors for residential AC units range from 35-80 µF. A reading below spec indicates failure.

3. Component testing and diagnosis

The technician will test the contactor for pitting or welding, check the dual-run capacitor (or separate start/run capacitors), and verify compressor windings with an ohm meter. If the compressor shows an open winding, shorted winding, or grounded circuit, it has failed and requires replacement.

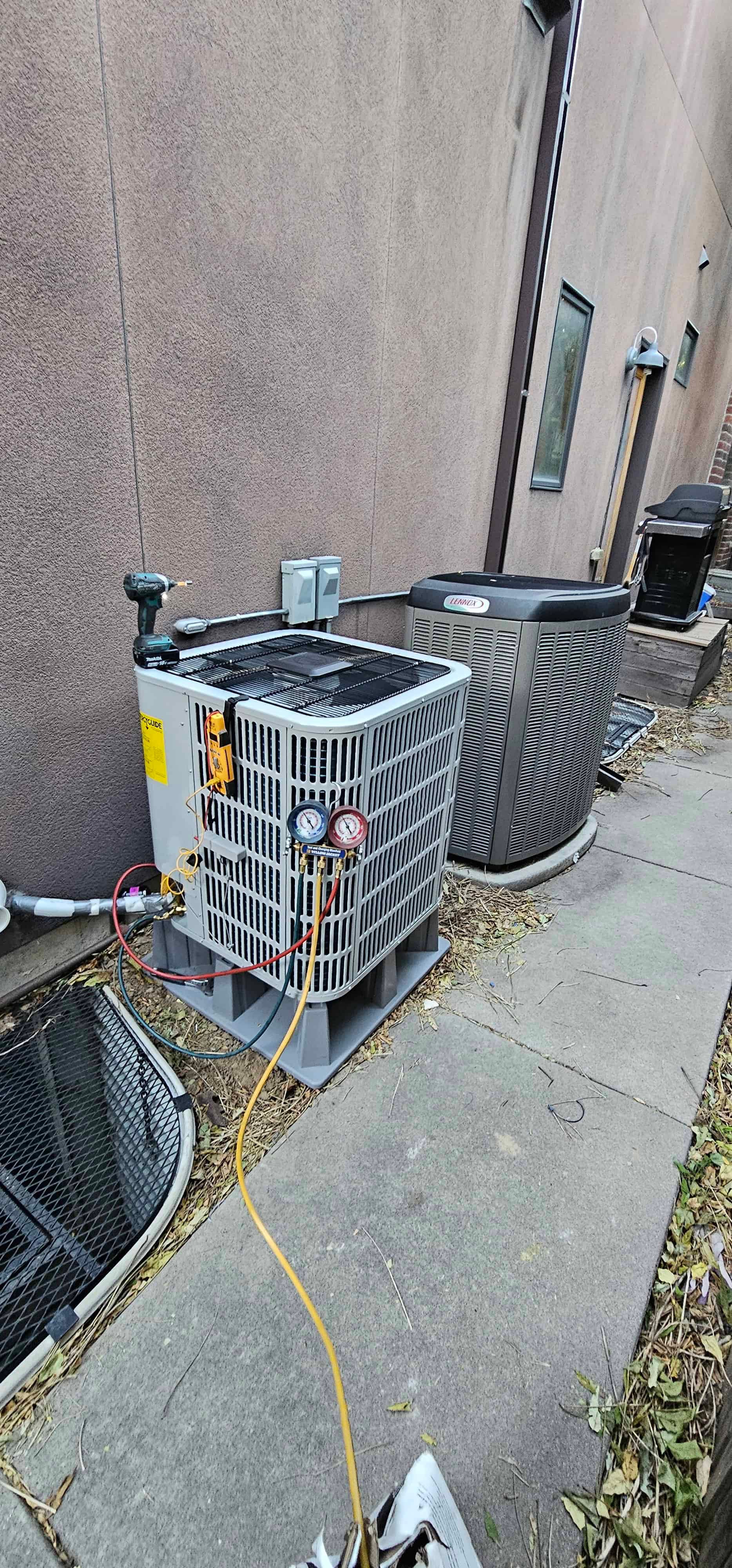

4. Refrigerant and pressure check

If the electrical components test good but the unit still won't run properly, the technician will attach refrigerant gauges to check system pressures. Low pressure indicates a leak, while high pressure can indicate a restriction or overcharge.

5. Repair estimate and options

Once the diagnosis is complete, the technician will provide a detailed repair estimate. For simple component failures (capacitor, contactor, fan motor), the repair can often be completed the same day. For major failures (compressor, control board, refrigerant leak), you may need to decide between repair and replacement based on the age and condition of your system.

When to repair vs. replace

- System under 8 years old: Usually worth repairing unless it's a compressor failure

- System 8-12 years old: Repair if cost is under $800; consider replacement for major repairs

- System over 12 years old: Replacement often makes more sense; repair costs add up on aging equipment, and new systems are 30-40% more efficient

How to prevent outdoor unit failures

While some component failures are unavoidable, you can significantly extend the life of your outdoor unit with basic seasonal maintenance. Here's what actually matters in Colorado's climate:

Keep coils clean

Cottonwood season in Denver is brutal for outdoor units. The fluffy seeds clog condenser coils and restrict airflow, causing the compressor to overheat and fail prematurely. Gently rinse the exterior coils with a garden hose 2-3 times per summer. Spray from the inside out (through the fan grille) to push debris away from the coils, not deeper into them.

Clear the area around the unit

Maintain at least 2 feet of clearance on all sides of the outdoor unit. Trim back shrubs, remove weeds, and don't stack storage items against the unit. Good airflow is critical; a blocked condenser will run hotter, work harder, and fail sooner.

Change filters regularly

The single most important thing you can do is change your furnace filter every 1-3 months. A dirty filter restricts airflow, causes the evaporator coil to freeze (see our AC freezing troubleshooting guide), and forces the outdoor unit to work harder than necessary. Set a phone reminder; this 2-minute task prevents expensive repairs.

Annual professional maintenance

A yearly tune-up catches small problems before they become expensive failures. During a maintenance visit, a technician will test the capacitor, check electrical connections, measure refrigerant levels, clean the condensate drain, and verify safe operating pressures. This costs $120-$180 but can prevent a $2,000+ emergency repair.

At UniColorado, we specialize in AC repair throughout the Denver metro area

We diagnose outdoor unit failures with electrical testing and refrigerant analysis; not guesswork. Our technicians carry common parts (capacitors, contactors, fan motors) on every truck for same-visit repairs when possible.

Need help with an outdoor unit that won't turn on? Learn more about our AC repair services or call us for a diagnostic appointment.