Most Furnace Noises Are Harmless; But Two Mean 'Turn It Off Now'

Your furnace makes noise. That's normal. Most furnace sounds are just the system doing its job: metal expanding, air moving, motors running.

But two sounds are dangerous. If you hear banging or metal scraping, turn off your furnace immediately. These sounds indicate potential gas buildup or mechanical failure that can damage your system or pose a safety hazard.

After 12,000+ installations, we've learned that most homeowners worry about the wrong sounds and ignore the dangerous ones. This guide helps you tell the difference. If your furnace keeps needing repairs or you're wondering if it's too old, see our guides on furnace repair vs. replacement and how to tell if your furnace is too old.

The Two Dangerous Sounds

Banging or Booming

What it sounds like: A loud BANG when the furnace starts, or repeated booming sounds while running.

What causes it: Delayed ignition. Gas builds up in the combustion chamber before igniting, creating a small explosion when the burners finally light. This is dangerous.

What to do: Turn off the furnace immediately. This is not a DIY repair. Call a professional. Delayed ignition can crack your heat exchanger or cause a fire.

Scraping or Metal-on-Metal

What it sounds like: A harsh scraping, grinding, or metal-dragging-on-metal sound, usually continuous while the blower runs.

What causes it: Loose blower wheel hitting the housing, broken blower mount, or a failing motor bearing. The blower wheel is spinning but something is rubbing or dragging.

What to do: Turn off the furnace. Continuing to run it will destroy the blower assembly and potentially damage the motor. This requires professional repair.

Sound-by-Sound Diagnostic Guide

Use this guide to identify what sound you're hearing, what's causing it, and whether it's urgent. Click each sound type to see details.

Quick Reference: Furnace Sounds at a Glance

Use this table to quickly identify urgency and whether you can handle it yourself or need a professional.

| Sound | DIY or Pro? | Details |

|---|---|---|

| Banging / Booming | TURN OFF: Call Pro | |

| Scraping / Metal Grinding | TURN OFF: Call Pro | |

| Squealing / Screeching | Call Pro Soon | |

| Whistling / Whine | DIY (replace filter) | |

| Humming | Ignore (if gentle) | |

| Clicking on Startup | Ignore (if stops after ignition) | |

| Rattling | DIY (tighten screws) | |

| Rumbling | Call Pro for Maintenance |

Normal Furnace Sounds People Worry About

Some furnace sounds are completely normal, but homeowners call us worried. Here's what's normal:

- Clicking when starting: The igniter clicking to light the burners. Normal. Should stop within 3-5 seconds.

- Gentle whoosh when burners light: That's the sound of gas igniting. Perfectly normal.

- Hum or whir when blower runs: The blower motor and fan moving air. Normal, especially on variable-speed systems.

- Occasional pops or ticks after shutdown: Metal ducts expanding and contracting as they cool. Normal, especially with new ductwork.

- Quiet vibration on startup: System coming up to speed. Normal, unless it's violent shaking.

The key: if a sound is new, sudden, or much louder than usual, it's worth investigating. Furnaces develop issues over time; a sound that wasn't there last week could indicate a problem.

Preventing Furnace Noise Problems

Most furnace noises (except normal operating sounds) are preventable with regular maintenance. Here's how to keep your furnace quiet:

1. Replace Air Filters Every 1-3 Months

A dirty filter restricts airflow, causing whistling and forcing the blower motor to work harder (leading to premature wear and eventual squealing). In Denver's dry climate with dust and pollen, replace filters every 1-2 months during heating season.

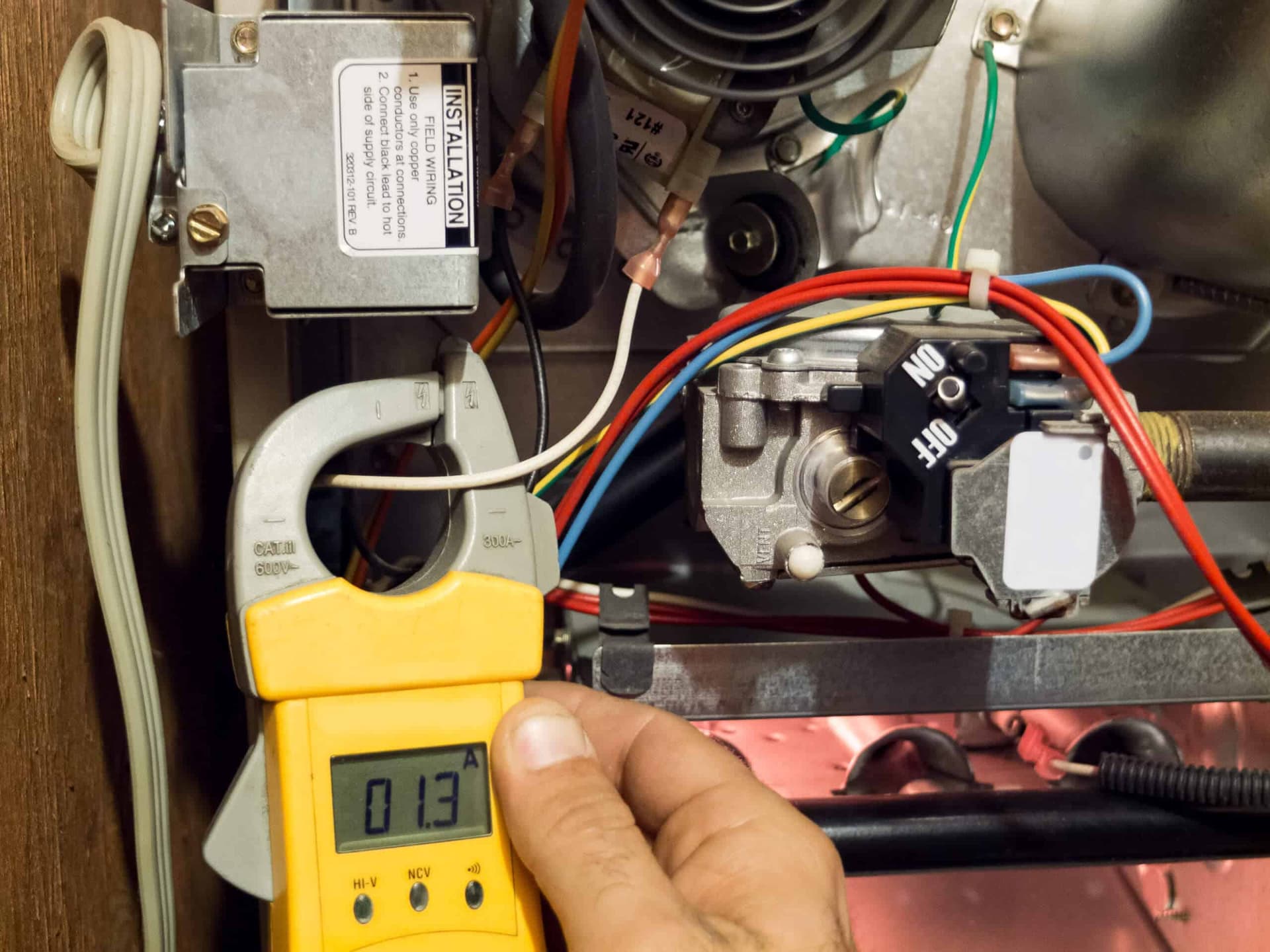

2. Schedule Annual Furnace Maintenance

A professional tune-up includes cleaning burners (prevents rumbling), inspecting the blower assembly (catches loose wheels before they scrape), checking igniter operation (prevents delayed ignition and banging), and lubricating motor bearings (prevents squealing).

3. Tighten Loose Panels and Ductwork

Once a year, check that all furnace access panels are secured and tighten any visible screws. If you have accessible ductwork in the basement, check for loose sections and secure with sheet metal screws.

4. Don't Ignore New Sounds

If your furnace starts making a sound it didn't make last week, investigate. Small problems (like a slightly loose blower wheel) are cheap to fix. Ignored problems turn into expensive repairs (like replacing a destroyed blower assembly).

At UniColorado, we include a full furnace inspection with every maintenance visit. We catch issues before they become noisy emergencies.